REVOLUTIONIZING RECYCLING:

LOYTEC’S SMART AUTOMATION

FUELS SUSTAINABLE PROGRESS

AIM Recycling Center.

The AIM facility at Saint-Augustin-de-Desmaures, a suburb of Quebec City, is the most advanced dry material recycling facility in North America. All the material sorting is done by high-tech equipment. More than 50 tonnes of dry material per hour is process by AIM. The building’s dimension and the companies operations required the use of the most modern technology to assure reliable operations, energy efficiency, and also personal security.

THE CHALLENGES

Ensuring System Reliability and Scalability

Complex Automation Requirements

Location

Saint-Augustin-de-Desmaures,

Québec, Canada

LOYTEC Partner

AIREX CONTROLS Inc.

LOYTEC Tools

L-LOGICAD

Solutions

L-INX Automation Servers

L-IOB Controllers and Modules

L-VIS Touch Panels

The Solution.

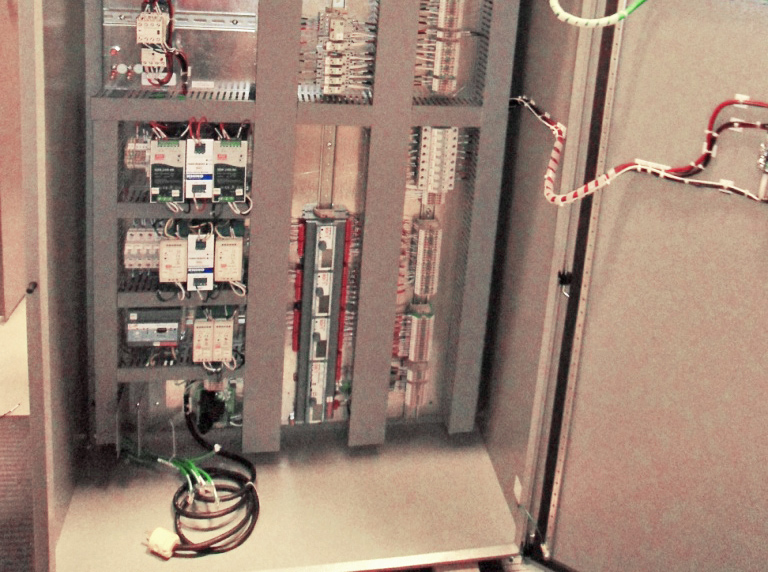

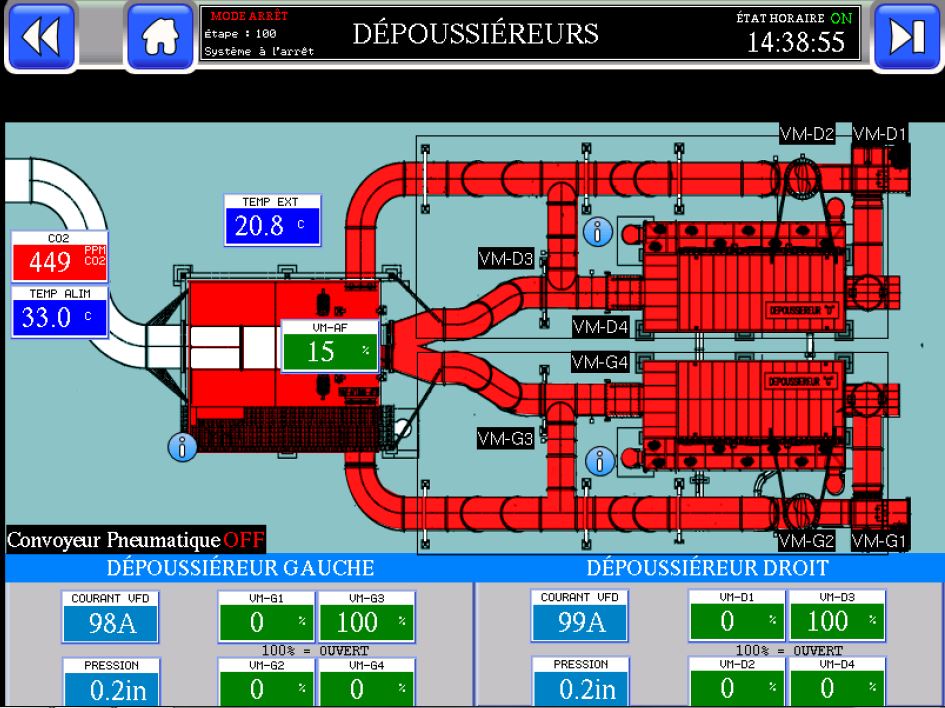

The AIM facility at Saint-Augustin-de-Desmaures, the most advanced dry material recycling facility in North America, required cutting-edge technology to ensure efficient and reliable operations. LOYTEC, through its Competence Partner AIREX CONTROLS Inc., provided a comprehensive automation solution tailored to meet these needs. The facility’s complex requirements were addressed using LOYTEC’s LINX-221 and LIOB-582 controllers, which formed the backbone of a dual dust collection system. This system, capable of managing a 100,000 SCFM air-flow make-up, ensures high air quality and optimal building conditions. The integration of these controllers, along with L-VIS Touch Panels and a complex L-LOGICAD control strategy, allows for seamless operations and easy scalability, all while ensuring that the facility’s stringent security and operational standards are met.

Benefits.

LOYTEC’s advanced automation solutions have brought numerous benefits to the AIM facility. The dual Ethernet network, configured in loops, ensures enhanced reliability and system resilience, a crucial aspect for a facility of this scale. The ability to add controllers without disrupting ongoing operations underscores the flexibility and future-proof nature of LOYTEC’s products. Additionally, the use of L-VIS Touch Panels, which provide remote access through the company’s VPN, simplifies daily operations and allows for real-time monitoring and adjustments. This level of control not only enhances operational efficiency but also contributes to energy savings and improved safety, aligning perfectly with the facility’s needs for modern, reliable technology.

Conclusion.

LOYTEC’s solutions have proven to be instrumental in the successful realization of the AIM facility’s automation requirements. By leveraging LOYTEC’s advanced controllers, sophisticated control strategies, and user-friendly interfaces, the facility has achieved a level of operational excellence that sets a benchmark in the recycling industry. The seamless integration, reliability, and scalability of LOYTEC’s products have ensured that the AIM facility operates at the highest standards of efficiency, safety, and environmental responsibility, making LOYTEC the ideal partner for such high-tech projects.

Creating the smart buildings of tomorrow - together.

Schedule a meeting with our team to discuss your upcoming project!