At the end of 2014, the extension of the district office in Sigmaringen, Germany was completed. The four-storied office building with 8,300 m2 accommodates 190 employees.

At the end of 2014, the extension of the district office in Sigmaringen, Germany was completed. The four-storied office building with 8,300 m2 accommodates 190 employees.

“We want to be modern and energy-efficient. It is all about reducing running costs in future”, states the former district administrator Dirk Gaerte at the groundbreaking ceremony in 2012. In order to fulfill these requirements, the following measures were planned:

- Thermal insulation of the building to on average approx. 25–30 % below the required levels of EnEV (German Energy Conservation Regulation) 2009.

- Efficient sunblinds control with conductance factor of ≤ 0.2 according to VDI 2078 and automatic slat adjustment according to the sun position.

- Use of efficient lighting installations with specific connected load of 2.5 W/(m²100lx) on average.

- Use of geothermal energy for heating and cooling

- Air-conditioning plants with efficient fans and heat recovery installations.

- Aspiration of outside air for air-conditioning plants via geothermal heat exchanger.

- Building automation system with energy efficiency class A according to DIN EN 15232, with demand controlled functions and user-oriented room functions.

The Automation Concept

Already in the planning stage it was clear that a common base for all technical and organizational processes in the building has to be created to ensure that the demanding requirements are met.

The planning department Heidemann und Schmidt created the necessary preconditions with a system-wide integral planning. The LOYTEC Competence Partner HGI, Heger Gebäudeautomation Ingenieurgesellschaft mbH, was commissioned to implement the building automation for this project. HGI is not only a pioneer in all things related to LonMark systems, but also known for its professional handling of technically demanding projects throughout Germany. A major reason for the successful implementation of planning was also the exceptionally good cooperation between all parties involved, starting from the planning department Heidemann und Schmidt, HGI as a contractor, LOYTEC, and last but not least the customer itself. From the very beginning, all protagonists have been working together in a targeted and solution-focused way.

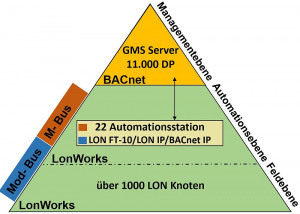

For HVAC and room automation, the district office Sigmaringen opted on the implementation of a LonMark system using both twisted pair and also Ethernet/IP networks as the basis for technical communication. BACnet has been defined as the protocol for the management level. In order to do without separate gateways, automation servers have been required that simultaneously integrate and automatically map standard protocols such as Modbus, M-Bus, LON, and BACnet. The LOYTEC Automation Servers LINX-150 and LINX-151 that have been chosen for this task meet both these conditions. L-IOB I/O modules were applied to connect physical data points. The LCD display on the I/O modules shows data point designations in clear text and data point states dynamically for all in and outputs.

Besides the automation servers for the entire control of heating, ventilation, air conditioning, and also higher-level room automation functions, LOYTEC also delivered all infrastructure products for the LonMark system.

Commissioning

As the distance to the construction site was more than 600 km, it was decided upon the commissioning of the 1,000 LON nodes and the LOYTEC automation servers via remote dial-in.

Each individual bus participant could therefore be imported, parameterized, respectively programmed in the database in advance at the office.

The devices were then handed over to the electrical contractor for the final installation. Commissioning respectively regulating was done by an on-site automation engineer and a programmer connected from the office.

These measures helped to reduce staff and travel expenses by 25 %.

The Building Management System (BMS)

A BMS was installed in parallel to the establishment of the automation network. By means of 22 distributed automation stations more than 11,000 data points are made available to the BMS where they are processed.

Functions like a web interface, plant graphics, schedulers, trend logs, and alarming with SMS forwarding allow the user to monitor also complex processes 24 hours a day and realize optimizations.

Result

The building is already in use since August 2014 and it appears that the ambitious objective regarding energy efficiency and sustainability has been achieved. The used heat recovery system and geothermal heat exchangers for the air-handling systems in combination with the intelligent individual room control concept reduced the energy consumption to an extent where the geothermal plant is sufficient to provide the minimum load for heating and cooling.

For covering peak-loads under extreme meteorological conditions, additional heat is obtained from the local heating system that has been built in the first construction phase (power house with woodchips and gas boiler).The power house is likewise connected to the overall automation network of the facility and also to the BMS so that all processes run automatically.

For implementation, the powerful L-INX Automation Servers with their various communication interfaces (M-Bus, Modbus, LON, BACnet) for the integration of twisted pair networks and different protocols on the Ethernet/IP channel have been extremely helpful. Hence, as required, throughout the entire project no additional gateways have been necessary. Thereby, the automated and fault-free connection of protocols by LOYTEC’s unique auto connect function has been proven effective once again.

LOYTEC’s emphasis on IP communication in combination with IT security features at device level supported HGI during commissioning and ensured high acceptance by all IT administrators involved. Extensive remote accessibility up to the programming level allowed for flexible system configuration and significantly reduced staff and travel expenses. Thereby, the possibility of performing program modifications during ongoing operations has been proven to be very advantageous.

Looking back, the demanding requirements for the building automation system have certainly been a great challenge for the system integrator. Thanks to the perfect, system-wide planning, the unique combination of functions of the LOYTEC automation servers, and the fair cooperation between system integrator and manufacturer, these challenges could have been perfectly mastered.

Interesting Facts

Devices: LIP-3333ECTB, LIP-33ECTB, LINX-150/151, LIOB-100/101, LIOB-A2, L-Proxy, LT-33, L-MBUS20

| Location | Sigmaringen, Germany |

| Number of Nodes | 1.031 LON nodes |

| Topology | BACnet IP, LonWorks FT10, LonWorks IP, IP Netwerk, Modbus RTU, Modbus IP, M-Bus |

| Companies involved | HGI Heger Gebäudeautomation Ingenieurgesellschaft mbH |

| LOYTEC Components | 6 x LIP-3333ECTB, 3 x LIP-33ECTB, 10 x LINX-150, 4 x LINX-151, 6 x LIOB-100, 11 x LIOB-101, 6 x LIOB-A2, 1 x L-Proxy, 19 x LT-33, 1 x L-MBUS20 |

| LOYTEC Tools |

- |